How does a vacuum sealer work?

Vacuum sealing food has become an indispensable tool for preserving freshness, extending shelf life, and saving space. But how does a vacuum sealer actually work in detail? Which components enable this process? And how can one optimally utilize the vacuum sealer to achieve the best results? In this article, we take a closer look at the functionality of a vacuum sealer and provide valuable tips for its application and maintenance.

What is a vacuum?

Before delving into the inner mechanism of a vacuum sealer, it's important to understand what a vacuum is. A vacuum is a space devoid of any matter, including air. In a vacuum, there is no pressure and therefore no air. In food preservation, a vacuum is utilized to remove air and thus oxygen from the packaging, which slows down the growth of bacteria and microorganisms, extending the shelf life of the food.

Components of a vacuum sealer

A typical vacuum sealer consists of several main components that work together to enable the vacuum sealing process. These components include:

- Vacuum chamber: This is the area where the food and vacuum bag are located, which is vacuumed. In external vacuum sealers, the vacuum chamber is formed by the bag itself, while in chamber vacuum sealers, it's sealed by a special lid.

- Vacuum pump: The vacuum pump generates the negative pressure that creates the vacuum in the chamber. It draws the air out of the chamber and the bag, creating a vacuum.

- Sealing bar: After the vacuum is created, the sealing tape carefully seals the bag to maintain the vacuum and prevent air from entering.

- Controls: These allow the user to control and adjust the vacuum sealing process according to the requirements of the food and personal preferences.

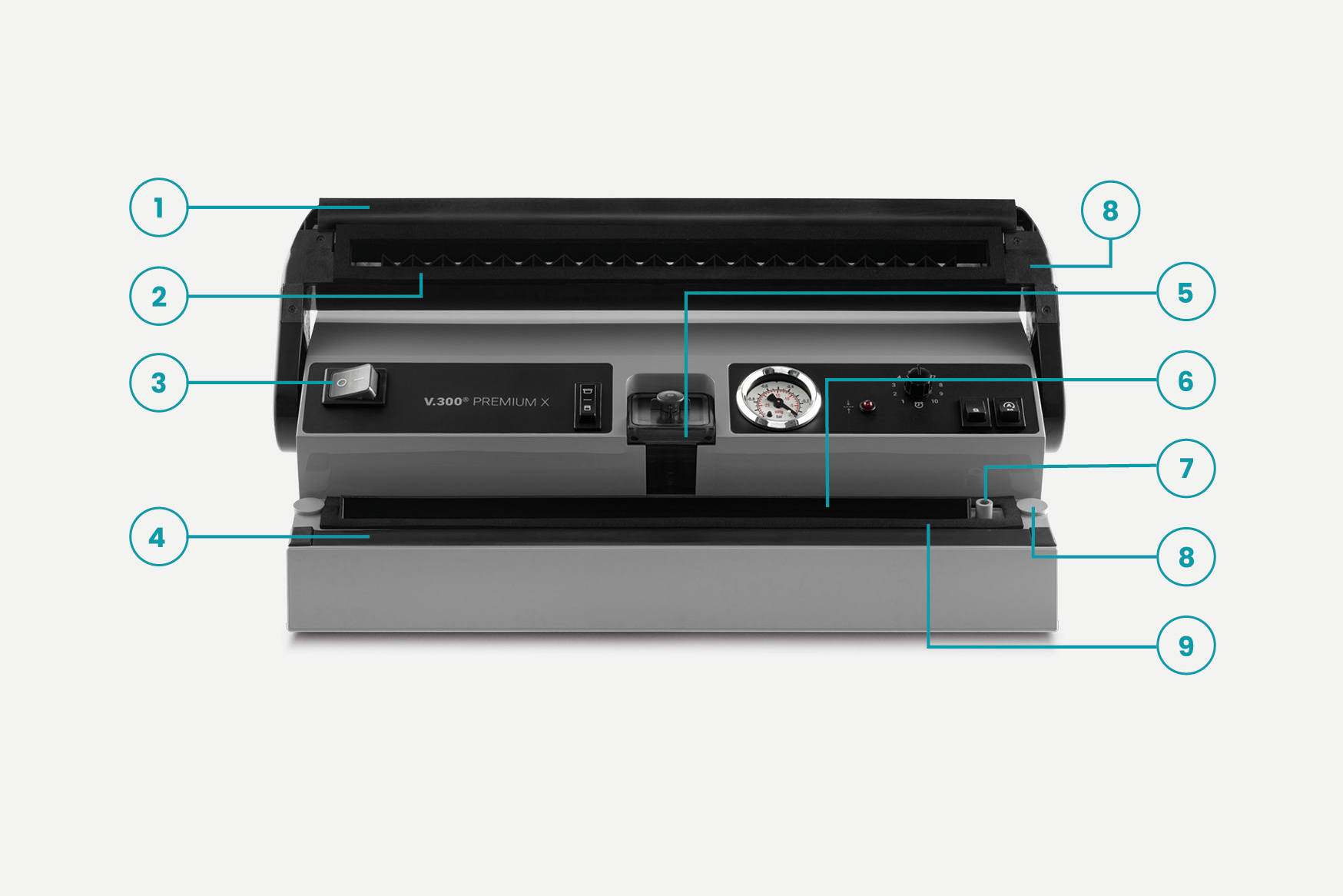

General assembly of a Lava vacuum sealer

- Hard rubber welding strip in the lid

- Foam rubber seal on top

- ON/OFF switch

- Sealing bar with glass fabric foil

- Removable liquid separator

- Removable bag stop bar

- Connection for vacuuming containers

- Magnet for LCS (Lava Close System)

- Foam rubber seal at the bottom

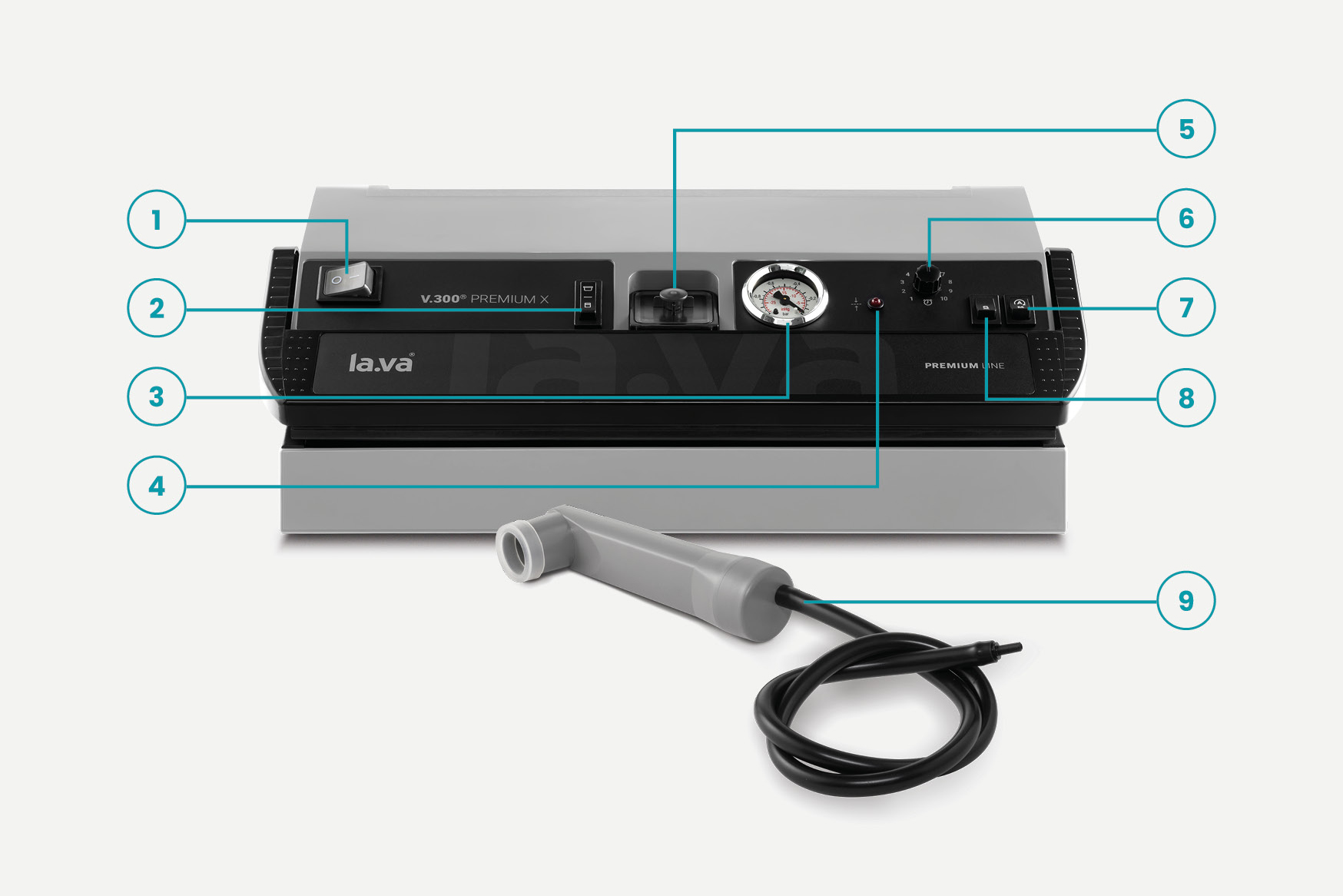

Overview of controls on a Lava vacuum sealer

- ON/OFF switch

- Selector switch for containers/bags

- Vacuum indicator (manometer)

- Control light for sealing process

- Lid with liquid separator

- Adjustment wheel for sealing time

- Selector switch for automatic/manual sealing function

- Start manual sealing process

- Vacuum suction device

The vacuum sealing process with a vacuum sealer

The vacuum sealing process begins by placing food items into the vacuum bag. The bag is then placed into the vacuum chamber of the device, and the lid (for chamber vacuum sealers) or the bag (for external vacuum sealers) is closed to seal the chamber. The vacuum pump then draws air out of the chamber and the bag, creating a vacuum. Once the desired level of vacuum is reached, the bag is sealed shut by the sealing tape to maintain the vacuum. The bag can then be safely removed and is ready for storage in the refrigerator or freezer.

Monitoring and regulating pressure during vacuum sealing

A high quality vacuum sealer monitors and regulates the pressure inside the chamber to ensure that the vacuum is generated properly. This helps to maintain consistently high quality of the vacuum-sealed food items.

Automatic vs. manual control in vacuum sealers

Lava vacuum sealers from the V.200 Premium X model onwards offer both automatic and manual control functions, simplifying and optimizing the vacuum packaging process. The choice between automatic and manual control depends on individual preferences and requirements.

Marinating function and application tips

A vacuum sealer enables faster and more efficient marination of food. This is achieved by the vacuum increasing the pressure inside the bag, allowing the marinade to penetrate the food more quickly. When vacuuming different types of food, it's important to follow the right procedure. For instance, delicate foods like berries or soft vegetables should be frozen first or vacuumed at a lower pressure with pressure regulation to avoid crushing.

Cleaning and maintenance of a vacuum sealer

To extend the lifespan of your vacuum sealer and ensure optimal performance, regular cleaning and maintenance are crucial.

Please consider the following points before cleaning your vacuum sealer:

- Always unplug the power cord before performing any cleaning tasks on the device.

- Perform cleaning tasks only when the welding bar is cooled down to avoid the risk of burns.

- Do not immerse the device in water or clean it in the dishwasher.

- Make sure to unplug the device before cleaning and ensure that no moisture enters the device during the cleaning process. Otherwise, electronic components may be damaged.

- After cleaning, make sure to thoroughly dry the device before using it again.

Tips for cleaning your Lava vacuum sealer

- Clean the device and accessories exclusively with a damp cloth and use a mild cleaning agent.

- Remove the bag stop bar for cleaning.

- Keep the foam rubber seals and the glass fabric foil clean at all times.

- Before each use, check the welding bar for cleanliness. If it is dirty, clean it only with a damp cloth. Do not use sharp or abrasive objects.

Replacement parts for your vacuum sealer

To ensure that you enjoy your Lava vacuum sealer for a long time, we provide spare parts for up to 20 years after purchase. Most wear parts can be easily replaced in just a few steps.

Conclusion

A vacuum sealer is an extremely useful tool in the kitchen, allowing you to keep food fresh for longer, save space, and simplify meal preparation. By understanding the operation of your vacuum sealer and using and maintaining it properly, you can benefit from all its advantages and elevate your food preservation to a new level.